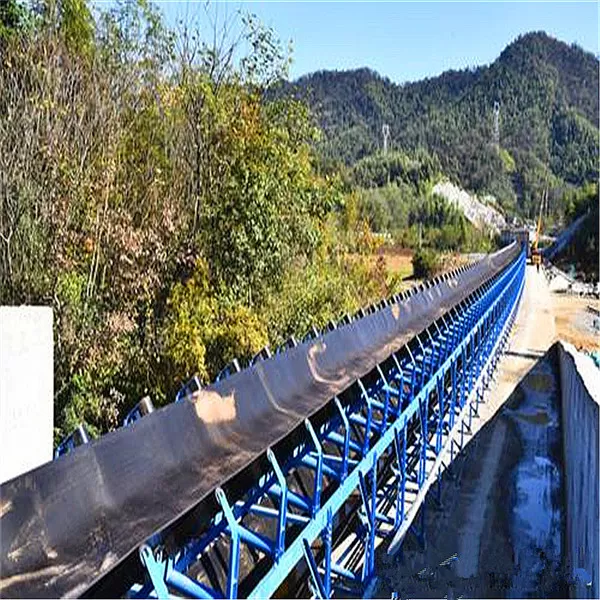

Long distance curved belt conveyor system for bulk material conveying

Product Details:

| Place of Origin: | China |

| Brand Name: | SSI |

| Certification: | mill certificate |

| Model Number: | customized |

|

Product: |

Belt Conveyor Systems |

Color: |

Blue |

|

Type: |

Convention |

Painting: |

International Top Brand |

|

Character: |

Long Distance And Curved |

Material Handling: |

Coal |

|

Belt: |

Fabric |

Feature: |

Durable |

|

High Light: |

Special designed according to application situation Reliable, reputation,high quality and cost effective. Global service available. |

||

Long-distance curved belt conveyor system for bulk material conveying

Shanghai Sunshine industry technology co., Ltd has been designing and supplying client bulk materials conveying systems for industries around the world for the past six years. Whether you are looking for a piece of equipment or a complete turnkey system, we are happy to offer you a customized solution, just customized to your specification requirement. We can provide bulk material handling systems for both new projects and existing systems. It`s used for handling comment material such as coal, clinker, aggregates, biomass products grain gypsum, iron ore, limestone, sulfur.

Belt conveyors have various structural type, including grooved belt conveyor, flat belt conveyor, climbing belt conveyor, side inclined belt conveyor, turning belt conveyor, etc. push plate, side baffle, skirt, and other accessories can also be added on the conveyor belt to meet various process requirements

specification of standard conventional conveyor belt

|