Grab Type Ship Unloader at Coal Power Station Port

General Information:

| Place of Origin: | China |

| Brand Name: | SSI-HDCZ |

| Certification: | manufacture certificate |

| Model Number: | Customized |

|

Material: |

Carbon Steel |

Painting: |

According To ISO12944 |

|

Color: |

Advise By User |

Capacity: |

800 T/h |

|

Character: |

Durable |

Advantage: |

High Performance |

|

Benefit: |

Low Cost |

|

|

|

High Light: |

satisfy client`s needs , specially designed according to the port application situatioln. , Reliable, reputation,high quality and cost effective. |

||

Product Description

Mechanical(electric)differential bridge-type ship unloader

Mechanical (electric) differential bridge-type ship unloader is a suite of effective, reliable and high performance unloading appliances customized to the port and terminal business handling dry bulk cargoes.

The ship unloader is installed on the port,unloading dry bulk cargoes(coal, ore, mineral powder, cement, coke, ash, grain etc) from vessel`s hold via grab bucket. Discharging dry bulk cargoes to the hopper, then to the conveyor belt via hopper. By conveyor belt the dry bulk cargoes are conveying to the stockyard for storaging.

Bridge-type ship unloader including self-propelled trolley type and wire rope drawing trolley type. Wire rope drawing trolley type including main and auxiliary trolley type and differential four drums trolley type. Differential four drums trolley type including mechanical differential four drums trolley type and electric differential four drums trolley type.

Mechanical (electric) differential bridge-type ship unloader is most advanced and widely used today. Its hoisting system, opening system and drawing system, are controlled by four drums. It was particularly designed for specializing in professional bulk handling solutions that provide very highest levels of performance.

|

model |

Self-propelled trolley |

Main and auxiliary trolley |

Mechanical differential |

Electric differential |

|

weight(%) |

100% |

80% |

60~65% |

60% |

|

stability |

1.4 |

1.5 |

1.7~1.8 |

1.7~1.8 |

|

Wire rope lengtg |

1 |

6 |

2.5 |

2.5 |

|

Power consumption |

1 |

2.5 |

1.1 |

1.2 |

|

Operating cost(%) |

100% |

95% |

90% |

90% |

|

Fault and maintenance |

Breakdown rate high and hard to maintain |

Breakdown rate low and easy to maintain but wire rope system is complicated |

Wire rope system is simple, easy to change gear reducer is specific design,hard to maintain and change |

Wire rope system is simple,gear reducer is standard,easy to maintain,electrical system is complicated |

|

Cost of fundamental and facilities(%) |

100% |

95% |

85% |

85% |

|

model |

Mechanical differential |

Electric differential |

|

weight(t) |

1100 |

1050 |

|

Rail distance(m) |

18~28 |

18~28 |

|

No of wheel |

40 |

40 |

|

Luffing mechanism KW |

90~110 |

90~110 |

|

Four drums mechanism KW |

Start 2X500KW |

4*400 |

|

Specification of ship unloader |

||||||||||||||||

|

vessel |

capacity |

unload time |

lift capacity |

weight of |

cycle |

one cycle |

density of |

rail |

rail |

wheel |

extending reach distance |

rear reach |

hoisting |

lowering |

trolley |

traveling |

|

DWT |

t/h |

hours |

T |

T |

|

s |

t/m3 |

m |

|

kN |

m |

m |

m/min |

m/min |

m/min |

m/min |

|

1000 |

340 |

2.94 |

10 |

5.5 |

61.82 |

58.23529412 |

0.85 |

16 |

QU80 |

350 |

23 |

21 |

90 |

100 |

120 |

25 |

|

5000 |

500-2000 |

2.5~10 |

12.5~48 |

7.3~28 |

67.42~71.43 |

52.56-53.4 |

0.8~0.9 |

10.5~20 |

QU80~100 |

245~600 |

24~28 |

8~16 |

100~160 |

120~190 |

150~240 |

20 |

|

8000 |

1000 |

8.00 |

25 |

14.8 |

67.57 |

53.28 |

|

20 |

QU100 |

350 |

28 |

17 |

135 |

150 |

180 |

20 |

|

20000 |

800-1000 |

20.00 |

22~30 |

13.3~14.8 |

55.56~67.57 |

53.28~64.8 |

0.85 |

16~22 |

QU80~120 |

330~530 |

24~38 |

21 |

12~135 |

135~150 |

180 |

20~25 |

|

30000 |

1250 |

24.00 |

32 |

19.6 |

63.78 |

56.448 |

0.95 |

16 |

QU100 |

505 |

33 |

14 |

135 |

150 |

220 |

25 |

|

35000 |

800~1600 |

21.88~43.75 |

22~40.5 |

12.8~25 |

62.52~76.19 |

54~57.6 |

0.85~0.95 |

14~24 |

QU80~100 |

330~530 |

27~31 |

11~19 |

120~135 |

135~180 |

180~220 |

20~25 |

|

50000 |

1250~1650 |

33.3~40 |

32~40 |

19.5~25 |

60~67.35 |

56.16~60 |

0.85~0.95 |

22~26 |

QU100~120 |

500~520 |

30~33 |

17~19 |

150~200 |

180~240 |

180~220 |

20~25 |

|

70000 |

1250~1750 |

40~56 |

34~42 |

20.5~25.75 |

52.08~68 |

53~69.12 |

0.85~0.9 |

22~30 |

QU100~120 |

500~600 |

32~40 |

16.5~27 |

160~220 |

190~240 |

180~240 |

20~25 |

|

100000 |

1000~1800 |

55.56~100 |

30~46 |

18~27.6 |

55.56~75.12 |

48~64.8 |

0.8-1 |

22~26 |

QU120 |

450~600 |

30~38 |

17~20 |

135~180 |

150~220 |

180~240 |

25 |

|

150000 |

1800~2100 |

71.42~83.33 |

45~52 |

27.2~31.5 |

63.16~66.67 |

54~57 |

0.90~2.4 |

24~28 |

QU120 |

600~736 |

39~41.5 |

19~24 |

160~200 |

190~240 |

200~240 |

20~25 |

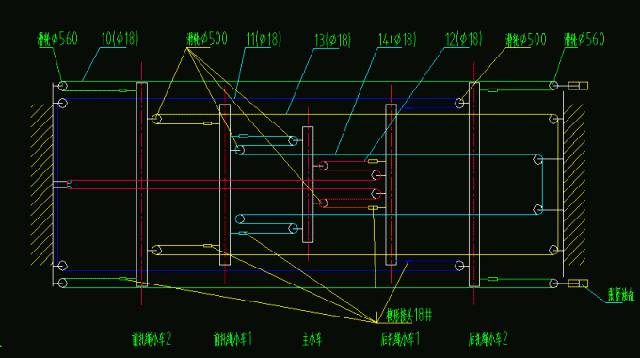

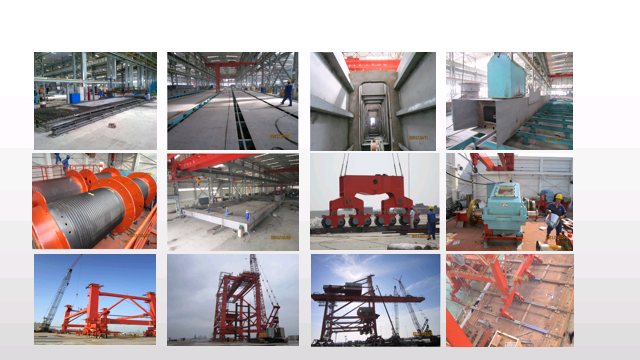

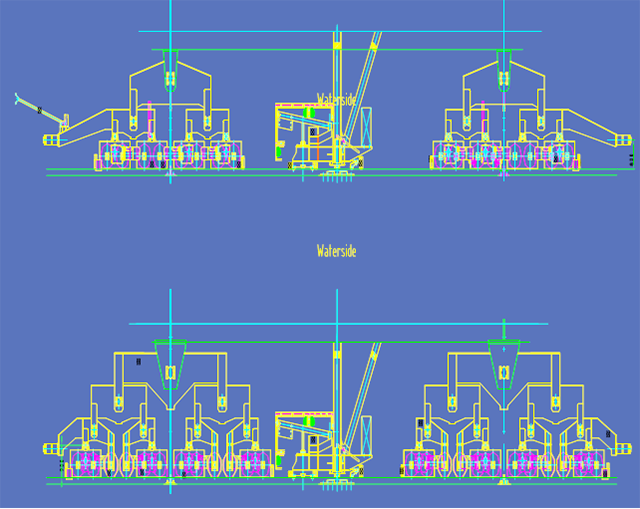

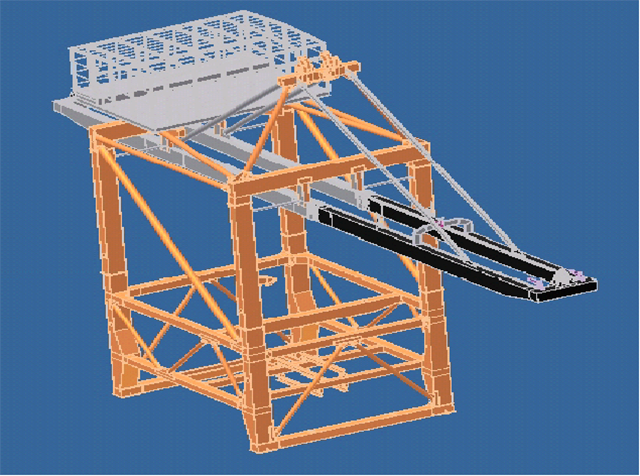

Main structure of bridge-type grab ship unloader

Mechanism of bridge-type grab ship unloader

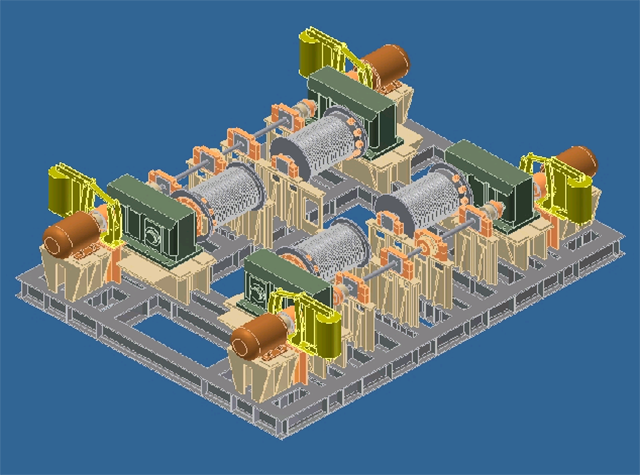

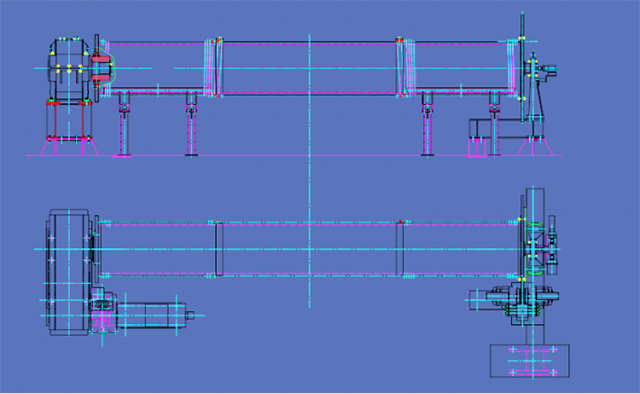

1.Traveling mechanism

The driving method of traveling mechanism is multi drive. Traveling mechanism is composed of driving device, traveling support device and safety protection device. The traveling support device adopts the wheel group with balance beam, the wheel adopts the rolling bearing wheel with double wheel edges, and the number of driving wheels shall not be less than 50% of the total number of wheels.

Most of the driving unit are three in one reducers, which can also be combined by reducers, brakes and motors through couplings

2. Main structure of bridge-type ship unloader

The connection of the main steel structure of the ship unloader adopts rigid connection, and the rigidity of the whole machine is strong enough.

Rolling T-section steel is adopted for the front and rear girder of the ship unloader and the trolley rail beam without fillet weld, to avoid weld fatigue cracking that may occur when the trolley wheels are rolled back and forth.

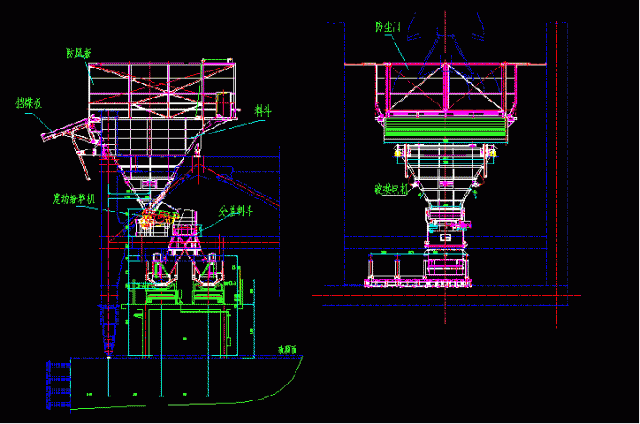

3. Hopper system

The hopper unloading system of the ship unloader is composed of coal hopper, feeder, fork hopper, coal spreading baffle, windshield, two way chute and buffer bracket.

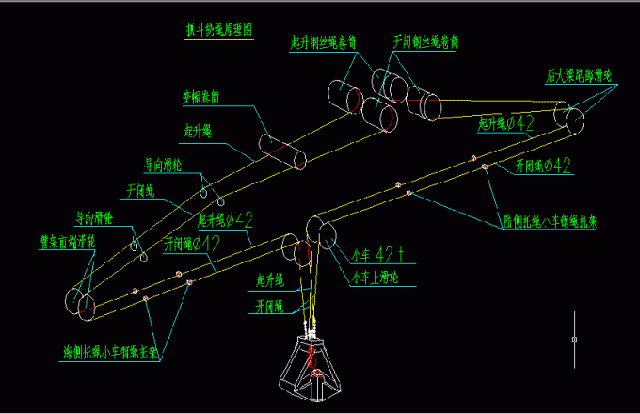

4. Grab bucket hoisting mechanism(mechanical differential four drums)

The traveling of the mechanical differential grab ship unloader trolley depends on a driving motor to connect the two differential reducers through the a coupling. Through the differential transformation of the gearbox, the grab lifting is transformed into the transverse movement of the trolley.

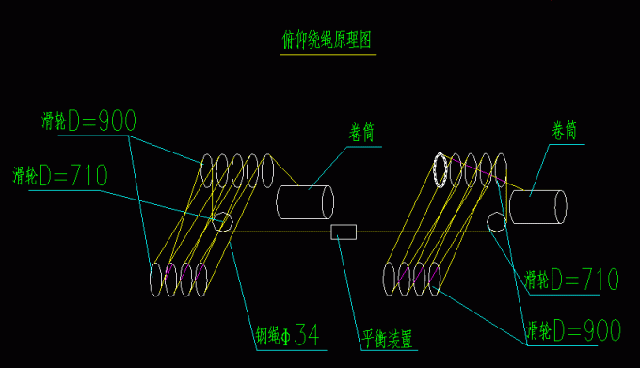

5.Grab bucket(wire rope reeving system)

6. Luffing mechanism

The luffing mechanism of bridge-type grab ship unloader is composed of motor, brake, reducer, drum and safety brake.

7.Wire rope reeving system of luffing mechanism

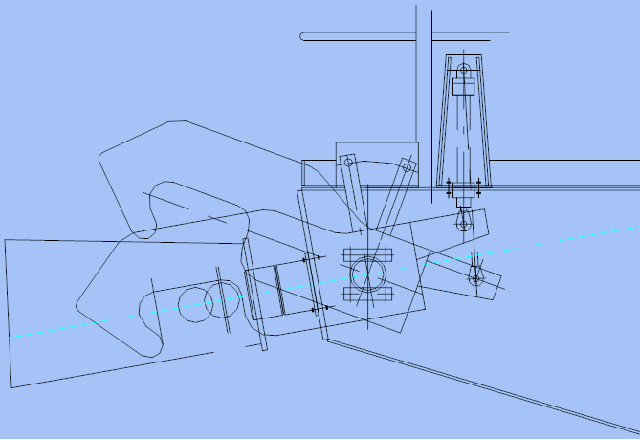

8. Cantilever safety hook device

When the cantilever of the ship unloader is luffing to 80 °, the safety hook device is used to hang the cantilever and loosen the steel wire rope at the same time. The safety hook is usually driven by hydraulic cylinder or electro-hydraulic actuator.

9.Wire rope reeving system of wire rope support trolley