luffing and slewing stacker

luffing and slewing stacker

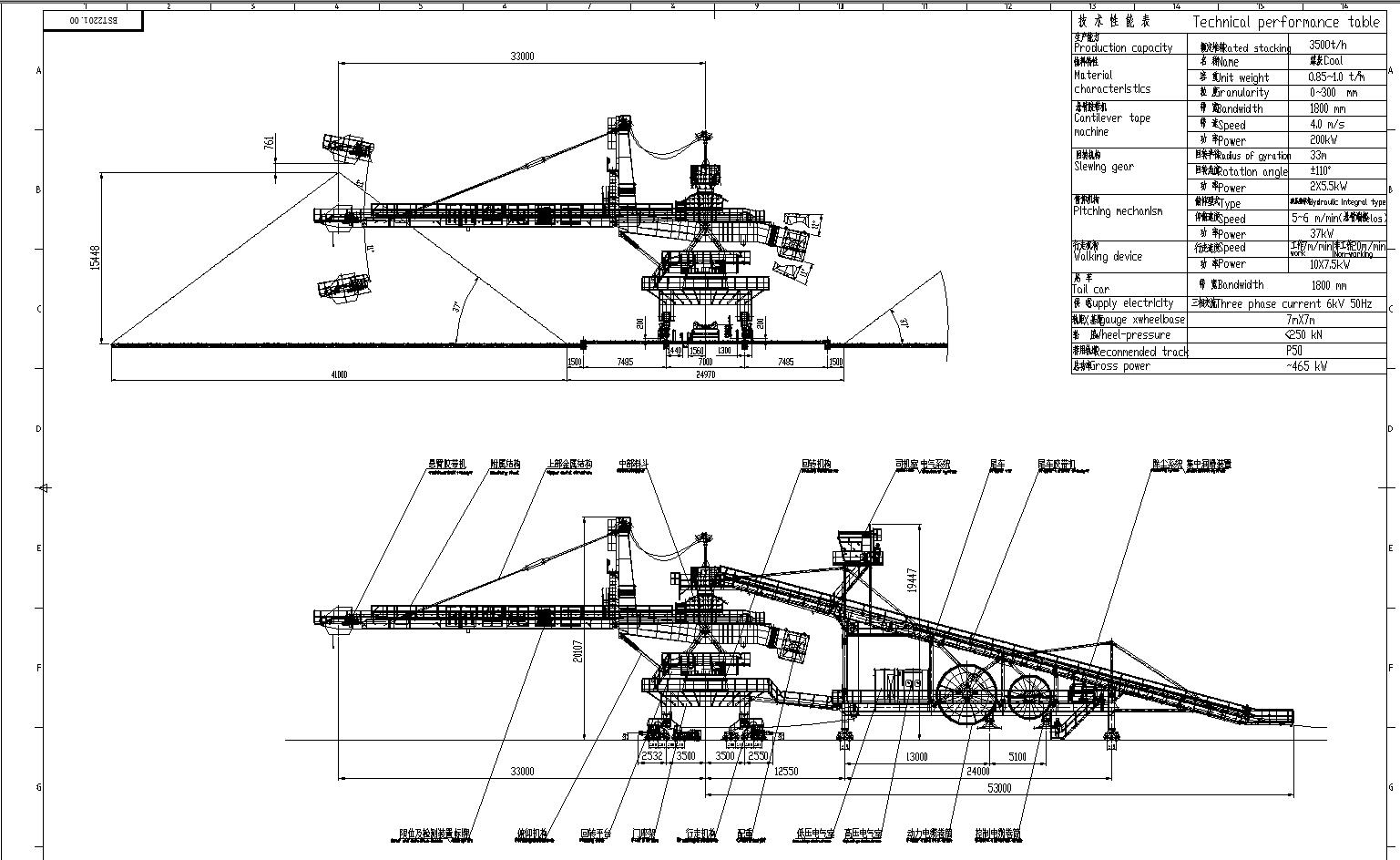

The luffing and slewing stacker is the most versatile type of stacker with 3,500 tons per hour capacity since it can slew from one stockpile to another on the other side of the yard, building uniform stockpiles on both sides of the yard feed conveyor. This stacker can build a stockpile in chevron, cone-shell, windrow, or strata stockpiling modes.

The bulk materials are unloaded to the cantilever belt conveyor via the feeding belt conveyor and feeding system of the stacker. And then transferred to the stockyard by the cantilever belt conveyor. In the stackyard area, the stacker can stack materials to form into zigzag, conical, and trapezoidal material piles through actions by traveling, slewing, and luffing.

The slewing cantilever stacker is mainly used for stacking limestone, sandstone, raw coal, and other bulk materials. It is mainly used for storing and blending materials in the stockyard. It is mainly applied for metallurgy, mining, building materials, chemical industry, cement, and other industries.

All the stackers are designed based on our client`s technical specifications and applications, so the technical discussion meeting is essential before the project proposal stage.

Table of equipment parameters

| description | parameter | unit |

| material | ore,sandstone,raw material | |

| density | 0.8~2.2 | t/m3 |

| granularity | <70 | mm |

| moisture | <2 | % |

| stacking capacity | 100~3500 | t/h |

| rail span | 4~8 | m |

| slewing radius | 15~40 | m |

| slewing angle | ±100 | ° |

| width of belt | 500~1800 | mm |

NOTICES

The customer shall provide the following information when placing order

- the character of bulk material;

- Stockyard information;

- Process flow chart;

- Power supply;

- Communication and control requirements.