Gas diffusion layer(GDL)

Carbon paper is a key material gas diffusion layer(GDL) for fuel cell systems. GDLs are hydrophobic carbon papers , coated with microporous layer, providing high electrical and thermal conductivity together with corrosion resistance.

SSI-GH is the first in China to use a roll-to-roll process to produce gas diffusion layers. At present, the maximum width of the product can reach 1.2m, which is more suitable for automatic production.The product has stronger electronic conductivity, stronger water management ability, excellent air permeability, high mechanical strength, appropriate rigidity and flexibility, excellent chemical stability and thermal stability under the advantages of ultra-thin,structural Tight and surface balanced for high durability. We have realized the full-process manufacturing and online process quality control from base paper-carbon paper-gas diffusion layer,and at the same time have better product consistency, and some product performance indicators have reached the international advanced level. At present, we have launched gas diffusion layer products suitable for air-cooled hydrogen fuel cells, liquid-cooled hydrogen fuel cells and cathodes of PEM water electrolysis hydrogen production electrolyzers.

Gas Diffussion Layer type for cooled hydrogen fuel cell

|

items |

Parameter

|

Model selection for fuel cell |

|||

|

GDL-S-16 |

GDL-S-18 |

GDL-S-20 |

GDL-S-22 |

||

|

1 |

Thickness(um)@50KPa |

160±20 |

180±20 |

200±20 |

220±20 |

|

Thickness(um)@1Mpa |

125±20 |

150±20 |

160±20 |

170±20 |

|

|

2 |

Resistance(mΩ•cm²)@1Mpa |

≤9 |

≤10 |

≤11 |

≤12 |

|

3 |

surface density(g/m²) |

55±5 |

58±5 |

60±5 |

65±5 |

|

4 |

Tensile strength MD(MPa) |

≥10 |

≥10 |

≥8 |

≥8 |

|

Tensile strength TD(MPa) |

≥6 |

≥6 |

≥5 |

≥5 |

|

|

5 |

Air flux(m³/(m²h) @0.1bar |

≥800 |

≥800 |

≥800 |

≥800 |

|

6 |

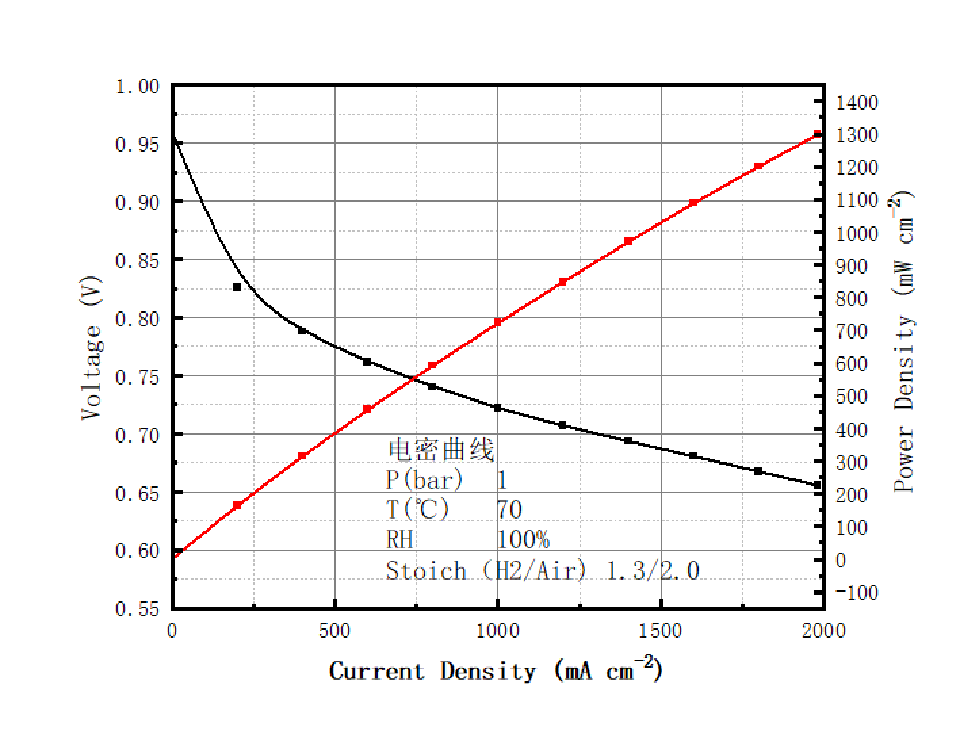

Polarisability(V)*@1500mA/cm² |

≥0.65 |

≥0.65 |

≥0.65 |

≥0.65 |

|

Polarisability(V)*@2000mA/cm² |

≥0.60 |

≥0.60 |

≥0.60 |

≥0.60 |

|

|

7 |

Contact angle |

≥150° |

≥150° |

≥150° |

≥150° |

|

8 |

Stiffness MD |

≥5.0 |

≥5.0 |

≥10.0 |

≥10.0 |

|

Stiffness TD

|

≥2.5 |

≥2.5 |

≥5.0 |

≥5.0 |

|

Apply to fuel cell stack,Fuel cell module,Fuel cell vehicle system integration.

GDL Selection Table for Electrolytic cell

|

items |

Parameter

|

Model selection for electrolytic cell |

||

|

GDL-D-24 |

GDB-D-22F |

GDB-D-22 |

||

|

1 |

Thickness(um)@50KPa |

240±20 |

220±20 |

220±20 |

|

Thickness(um)@1Mpa |

210±15 |

180±15 |

180±15 |

|

|

2 |

Resistance(mΩ•cm²)@1Mpa |

≤9 |

≤9 |

≤9 |

|

3 |

surface density (g/m²) |

100±5 |

85±5 |

85±5 |

|

4 |

Tensile strength MD(MPa) |

≥9 |

≥9 |

≥9 |

|

Tensile strength TD(MPa) |

≥6 |

≥6 |

≥6 |

|

|

5 |

Air flux(m³/(m²h) @0.1bar |

≥800 |

≥800 |

≥800 |

|

7 |

Contact angle(MPL side)MPL |

≥140° |

/ |

/ |

|

Contact angle(Carbon paper side) |

≥120° |

≥120° |

≤90° |

|

|

8 |

Stiffness MD |

≥11 |

≥11 |

≥11 |

|

Stiffness TD

|

≥6 |

≥6 |

≥6 |

|

Apply to Proton exchange membrane (PEM) electrolytic water hydrogen production equipment.

GDL Selection Table for Air-cooled hydrogen fuel cell

|

items |

Parameter

|

Model selection for aerospace&power station |

|

|

GDL-F-20 |

GDL-F-22 |

||

|

1 |

Thickness(um)@50KPa |

200±20 |

220±20 |

|

Thickness(um)@1Mpa |

150±15 |

165±15 |

|

|

2 |

Resistance(mΩ•cm²)@1Mpa |

≤8.5 |

≤9 |

|

3 |

surface density (g/m²) |

60±5 |

65±5 |

|

4 |

Tensile strength MD(MPa) |

≥8 |

≥8 |

|

Tensile strength TD(MPa) |

≥5 |

≥5 |

|

|

5 |

Gas permeability(m³/(m²h)@0.1bar |

≥900 |

≥900 |

|

7 |

Contact angle(MPL side)(MPL) |

≥140° |

≥140° |

|

Contact angle(Carbon paper side) |

≥120° |

≥120° |

|

|

8 |

Stiffness MD |

≥10 |

≥10 |

|

Stiffness TD

|

≥5 |

≥5 |

|

Apply to :

Hydrogen unmanned aerial vehicles;Hydrogen bicycle;Portable Power.

|

City Cluster |

GDL Annual Output |

GDL Width |

|

Shenzhen |

One hundred thousand square meters |

400mm |

|

Tianjin |

One million square meters |

The maximum width can reach 1.2m,depending on the needs of our customers. |

Features

Strong conductivity

Strong water management ability

Excellent air permeability

High mechanical strength

Long durability

Smooth Surface

GDL for fuel cell’s Performance measured in mass production batches:0.655 V@2000 mA/cm2